Dangers

- flood

- Screwdrivesr

- Wrench

- PTFE tape

- Silicon grease If in doubt call a professional!!

- Help Forum

Tools needed

Ballcock repair

READ THE DANGERS SECTION

The idea of this is so you get an idea of your system, so you know if your engineer is doing his job correctly, if you attempt a repair yourself,be careful

There are many types of ballvalve, in toilets, tanks, cylinders etc. These valves are also called float valves, ballcocks, torbeck valves. This guide is to show you how to repair one. Initialy you will need to turn the water off, if you dont know how, see here . There are many types of this valve, look at the pictures to find yours.

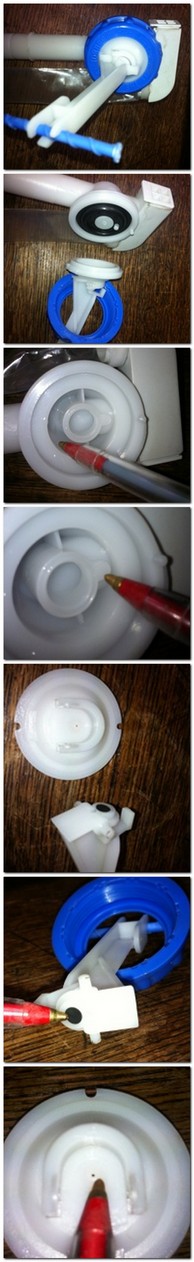

TORBECK VALVE - your genuine torbeck valve usualy has a blue main nut, copies are often white. The defining characteristics are a short, light duty arm, and the broad head to the valve. This valve uses the pressure of the water to close the valve, not a manual crank arm like others.

Assuming the water is off, unscrew the blue knurled nut all the way off, removing the arm, float, and face from the valve. set this aside and carefully remove the black rubber washer from the valve body, noting how the sharp metal pin passes through the washer, (Picture 4, Missing on the demo valve!) through a small white bush.

Set the washer aside too, and pick out the blue filter screen from the body, (again missing from demo valve, picture 3 shows location) noting how it comes out, and set aside. Ok, first off, run a little water through the valve body, by opening the isolation valve a little, just to flush out the the debris. Wash the filter screen, and replace in the body.

Inspect the washer, it should be flexible and should not leave black marks on your fingers, it should be clear of cracks and splits. assuming its ok, inspect the metal pin fixed into the valve body, it should be bright and shiny and not covered in scale or rubber debris, if it is, a little drop of vinegar or a rough cloth / small scraper will help. When clean, refit the washer, putting the pin through the white bush, offset in the washer.

Now all you are left with is the arm/face/float assembly. Inspect the float, most are open bottomed type, which rarely fail, some are enclosed type which you must check for water. Assuming all is ok, remove the float/arm assembly from the face. It clips down out of two plastic hooks, be gentle.

On the back of the arm is a tiny rubber washer that buts against a pinhole on the valve face. Check for marks in the rubber, debris and scale, clean where necessary. Clean the pinhole carefully, if you scratch it it will not work.

Now re assemble!

This type of valve does not shut off immediately the float is lifted, it takes a moment, adjust the water level by actual fill, not float height. Loads of spares are available for this valve, plumbcentre, ebay etc has washers,

most copy valves have the same internals. Often the best thing to do is buy a new valve, and just fit the guts of it to your valve - 10 minutes and a new valve is fitted without the need to drain/fight with spanners etc. Bargain!

NOTE - it is never possible to change this valve's internals live.

PART 1 VALVE - commonly known as 'straight arm ballcock', the original ballcock if you will. Now superceded by part 2, due to water regulations, but we wont go into that here. Ok, water off, pinch the split pin holding the arm flat, and twist/pull it out. (Never replace this with a mild steel split pin, it will rust and you will get a flood) do this with the water level LOW or you will strain the arm crank. The arm/ball will drop free. As you set this aside, give it a shake to check for water in the ball. ALways replace a ball like for like - if its a copper ball theres a reason for it usualy. Now with two sets of grips unscrew the main body of the valve from the carrier section. Be careful, there is a washer and a plastic jet unit. Now with the main body free, grip it with a wrench and unscrew the end cap, and shake out the slide. Ok, inspect the arm for cracks and the removed body for excessive wear, run a little silicone grease round the inside of the body with your finger. Take the brass or plastic slide carridge and inspect the washer, (usualy captive inside the body), if damaged, replace by picking it out, (small screwdriver) or cheat and turn it over. put a dab of grease in the slot in the slide and set aside. Inspect the plastic jet (like a volcano with a hole in it) pay particular attention to the tip - if it shows signs of deterioration or cracking, replace, remember - RED - low pressure feed, WHITE - high pressure - mains, BRASS - special applications - baine marie feeds etc. replace like for like - plumb centre, ebay etc, the size is based on the inlet pipe size 15mm/ 1/2" or 22mm / 3/4", etc, Most are 1/2". In deperate situations, file the tip back to a good flat surface with rounded edges.(remove as little as possible) This will mean massive adjustments to the arm though, when refitted.

Reassemble, and move the arm to check its free. Replace on carrier, ( make sure the water level is low so your not fighting the action of the arm and risk cross threading it), now refill the tank, and check the level, (idealy minimum 75mm below water outlet), if its wrong, grasp the arm close to the valve and close to the ball and bend the arm a little, bend down to lower the level, bend up to increase it. Dont forget to make sure the split pin is split, or it will flood. Again, you can just change the body of this valve, most are interchangable. This valve can be done live, but I dont recommend it.

PART 2 - or 'bent' arm valves, all follow the same principle, a bent arm, (to keep the water inlet high above the water) a large front face, like a torbeck, and an offset pivot point. Ok, water off, and unscrew the main knurled nut, the arm, ball and face will drop off. Note the cutout in the body and the raised bit in the removed face, this is to make sure the arm is correctly orientated. Now remove the main body from the carrier, by undoing the main nut. There is a plastic orifice section and a fibre washer. Check the ball, all rules in the section above apply, and inspect the push pin that runs through the center of the front face, replace if damaged. In the main body there is a 'belows' style washer - note its orientation, it goes in one way. Check for cracks, splits and deterioration. Also look for marks in the very center, on the 'orifice' side - even a small mark can cause a drip. Inspect the orifice tip (as above) and replace as necessary. Do not grease, and re assemble. To set the water level on this type you have to loosen the bolt at the back of the ball and slide it up and down the arm, rather than bending it. There are many types of this valve, some are plastic, some brass, all have the same characteristis of big flat face/ offset hinge location / center push pin. Virtualy all take the same washer, easily available from plumbase / plumbcentre etc

Valve Notes

- Hold the ballvalve open and see if the overflow can cope with the full incomming flow, if it cant, close off the isolation valve till it can

- It takes a while to fill a tank, and the last bit takes ages, hold the valve down to fill it the last bit, releasing it occassionaly to check if its reached 'level', Then run the tap to check your right!

- Working on live mains water is the quickest way to a flood